Wireless Digital Gauge “μMATE+”.

~ Improve manual measurements with digital measuring instruments that increase work efficiency

October 25, 2022

Magnescale Corporation (hereafter referred to as “Magnescale”) has released a manual digital measuring instrument, μMATE+, which will be exhibited at JIMTOF2022, held at Tokyo Big Sight from November 8 to 13, 2022.

Many dial and “lever type” indicators, are used in the assembly, processing, and inspection of manufactured parts, but most of them are still analog, and are used to visually read and record values on an analog dial, or to make a No/NoGo judgment within a tolerance. On the other hand, many facilities are considering transitioning from analog to digital data to save labor and improve efficiency, but the transitioning to digital dial indicators requires design and construction of the entire system, which is a high hurdle to achieve. We have listened carefully to the problems in the field and released a wireless digital gauge that is highly accurate, easy to measure, and makes the transition to digital data easy.

Point

(1) As lightweight and compact as analog gauges (lever gauge: approx. 75 g)

(2) Easy-to-read and easy-to-operate 2.7-inch color LCD touch panel

(3) Supports wireless smartphone operation, data storage and processing

(4) Two new technologies that enable high-speed, high-accuracy measurement (patent pending)

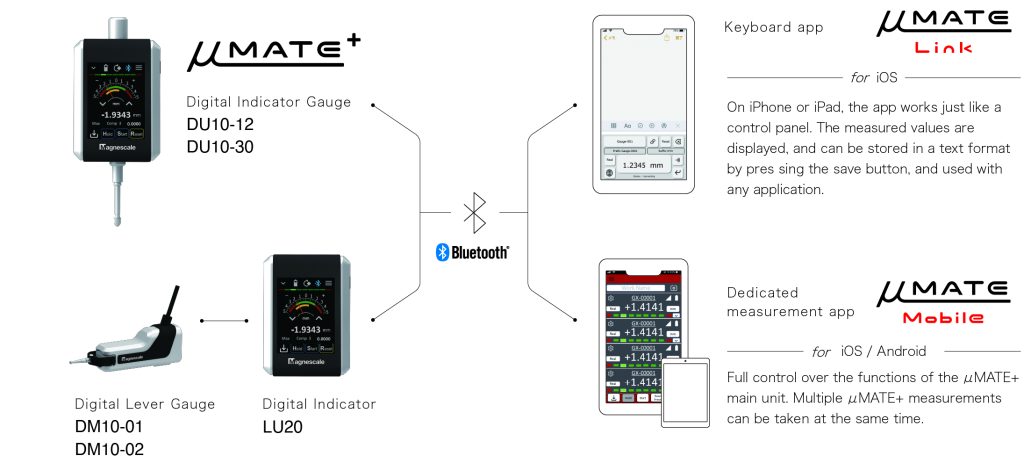

Product lineup

Choose from two types of digital indicator gauges and digital lever gauges. While used for the same applications as analog versions, these products add the advantages of digital data collection. The main unit can wirelessly transmit measurement values to tablets and smartphones via Bluetooth communication. Free iOS and Android apps are available to control the unit and acquire data. (Fig. 1) Data can also be transferred from the main unit via USB or microSD card.

Development of new technology

We have developed two new technologies to achieve high accuracy and high resolution. (Patent pending)

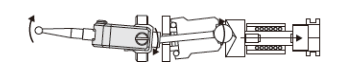

(1) AL link mechanism (Arc-to-Linear mechanism)

Many dial indicators use linear motion or lever motion that converts gear rotation to move the dial indicator. Using gears causes backlash, which results in measurement error. Magnescale has developed an “Arc-to-Linear” mechanism that precisely converts the circular motion of the tip of the gauge into linear motion, thereby detecting position without backlash (Fig. 2). This mechanism achieves repeatability of 0.5 μm or less.

(Fig. 2) AL link mechanism

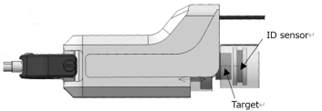

(2) ID sensor (Inductance to Digital conversion sensor)

A newly developed ID sensor is used to detect the amount of movement. The sensor has a compact and simple structure as shown in Fig. 3, and detects the change in inductance according to the amount of movement as an absolute value.

(Figure 3) ID sensor

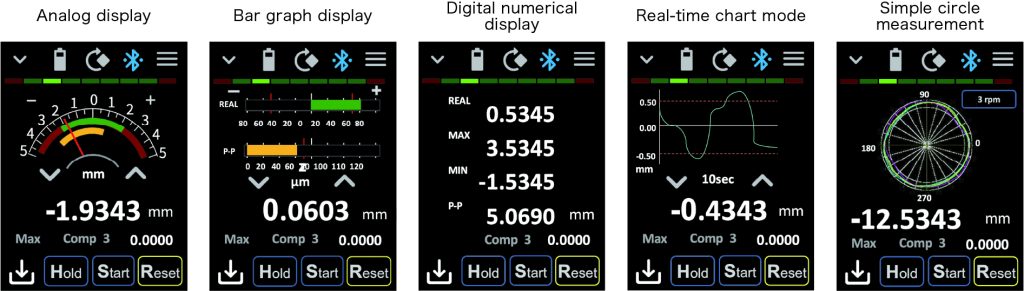

Large, easy-to-read display and a variety of measurement views

A large, easy-to-read 2.7-inch LCD display panel is used, and five display modes are available to match the conditions of the object to be measured. (Fig. 4) In the display mode that mimics the movement of an analog needle, the familiar “runout” sensation of conventional dial gauges and lever gauges is used. Even in case like there, the digital value is saved, so it is possible to record it as a numerical value. In addition, you can select the most suitable display for your measurement purpose, such as bar meter, real-time chart, circle measurement mode, etc.

(Figure 4) Five display modes

Sales Plan

Orders will be accepted from January 2023, and shipments will begin in April 2023. The sales target for the first year is 5,000 units per year, with sales of 50,000 units per year expected in a few years. The price is planned to be around 100,000 yen per set.

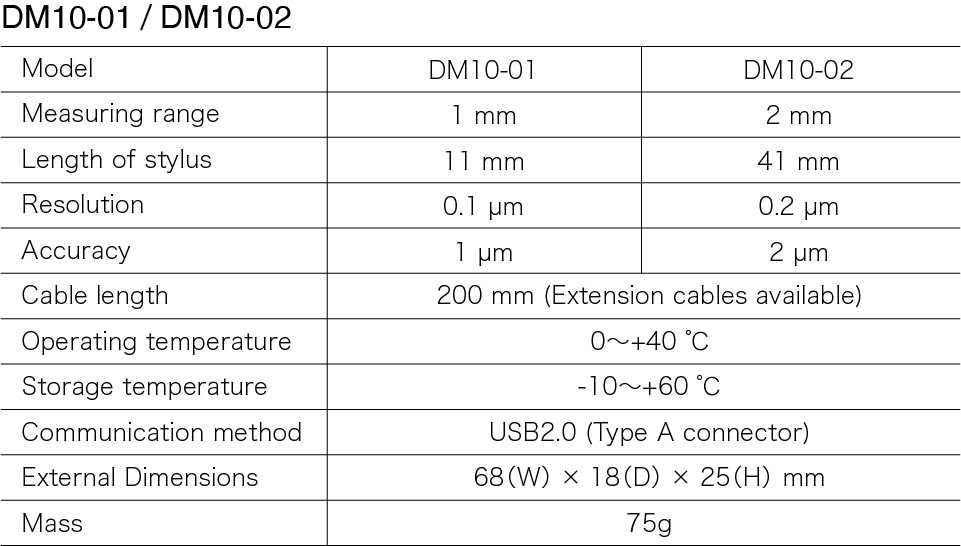

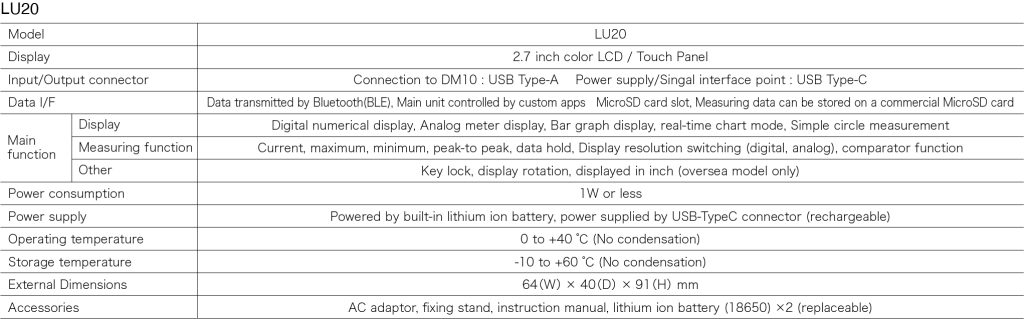

Main product specifications

About Magnescale Corporation

Magnescale Corporation has been providing high-precision position detection systems based on magnetic and laser detection principles to the machine tool and industrial machinery industries for more than half a century. Our ”Magnescale” products utilize the characteristics of magnetism to achieve reliability in harsh environments such as metal cutting. Our “Laserscale” product have achieved the world’s highest resolution of 2.1 picometers, contributing to the quality improvement of cutting-edge semiconductor manufacturing equipment and ultra-precision processing machines. The “Digital Gauge”, which uses a high-precision magnetic position detection system, digitally in-process/post-process inspection in manufacturing and assembly applications. Magnescale Corporation is also accredited as a calibration service provider for length and angle by JCSS, and provides products traceable to national standards.

Inquiries on this matter should be directed to

Magnescale Corporation Public Relations Division

45 Suzukawa, Isehara-shi, Kanagawa 259-1146

E-mail: informationPR@magnescale.com

TEL:0463-92-1011 URL: https://www.magnescale.com