Creating cutting-edge semiconductor products and scales to fit the needs of the constantly-evolving machine tools industry requires that we meet the ongoing needs of our customers. Giving thought to our semiconductor roadmap, the direction of the industry, and the demands of our customers, we set out a highly precise roadmap, and spare no effort in research and development to make it a reality. To develop new devices and pm resolution scales, a system to rate the process must be developed at the same time. Design and development methods must also constantly progress. Engineers in the fields of physics, chemistry, electricity, machinery, and software all work together to further enhance the functions of the Magnescale and Laserscale. We maintain our basic technological expertise following our own roadmap as an organization that rapidly and flexibly develops products that fit our customers’ needs, doing everything to retain our customers’ trust.

Mechanical design

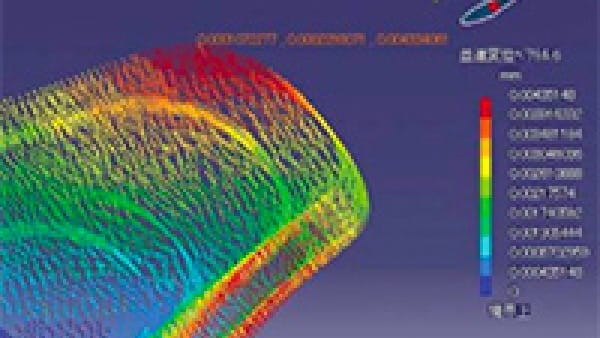

Convertible simulations with modal analysis

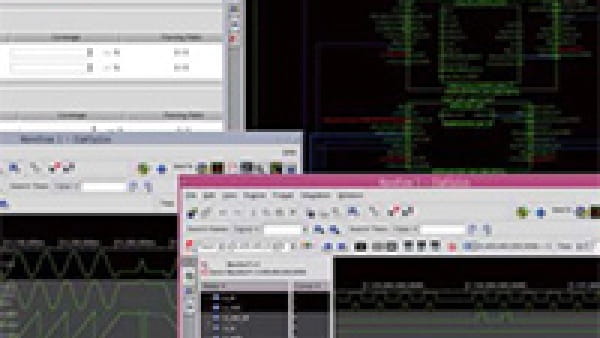

Signal delay testing with LSI wiring layout

The new absolute Magnescale, created from our magnetic technology, is the first high-accuracy magnetic scale with resolution at units of 0.01 ?m. Just as the optical scale detects changes in permeability of a lattice of light, the head of a magnetic scale detects the amount of flux in the magnetic lattice contained inside a magnetic medium. In order to achieve a high resolution in a magnetic scale, a high-quality magnetic medium and low-distortion head are essential. We used our specialized production and manufacturing equipment to develop a high-density magnetic media with the durability required for use in various environments. The heads are created with HDD-improved magnetic resistance, and the unique design pattern allows emission of magnetic signals with high accuracy and minimized distortion.

Additionally, we succeeded in creating the first magnetic scale with M-code signal detection. The signal from the head goes through our unique correction circuit, eliminating the negative effects of DC signal composition as well as phase and amplitude imbalance between sign and cosign signals, finally matched with the M-code at high resolution and precision to form an absolute position. The new Magnescale utilizes position-control to function in a variety of industrial environments with vapor or oil, locations that would be impossible for optical scales using a light lattice. The Magnescale also uses the same linear expansion coefficient as cast-iron, the base material for machines, allowing it to withstand surrounding temperature changes that machines are subjected to while delivering stable and accurate results.

The Magnescale achieves both increased precision and durability.

Image of magnetic scale recording

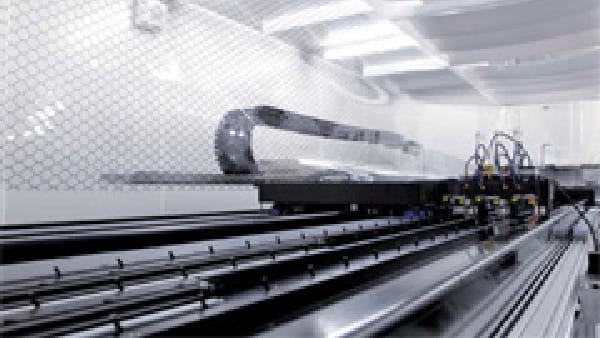

High-precision measurement system with long measuring range

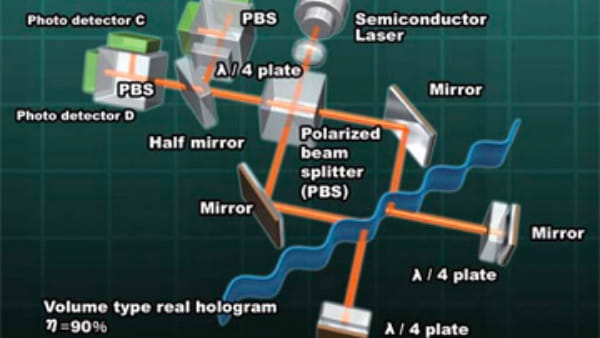

The Laserscale, which uses a semiconductor laser and volume hologram, is a special type of grating interferometer scale. As described by the detection diagram below, the laser passes through the polarized beam splitter, thereby being split into P and S waves. The divided laser is diffracted from a 550 nm cycle hologram lattice, onto a mirror with a 4 nm phase plate. Being reflected from the mirror, the P and S waves are reversed and returned to the hologram lattice, where they are diffracted for the second time. After diffraction, the laser returns to the splitter, and since the P and S waves have been reversed, it bypasses the emitter and reaches the receiver, where it passes through the splitter and interposes. With normal interferometers, changes in temperature can affect the light source wavelength, or changes in the air’s refractive index can produce errors, however the bilaterally symmetrical beams of our Laserscale cancel the effects of light wavelength changes and fluctuations or pressure changes in the air. By using double diffraction, the beam travels 550 nm around a hologram lattice, allowing interposition intensity with 4 light inversions. As a result, a position signal with a 138 nm cycle is detected by the receiver. As the volume hologram diffraction level is high and the signal has a favorable S/N level, the signal forms a perfect sine wave with 17 pm resolution at 8,000 divisions.

A 17 pm resolution is 1/3 the length of a hydrogen atom. Using the full extent of our exclusive laser technology, the optical system offers not only high accuracy and stability, but also excellent movement functions and response, gaining praise from our customers in fields that demand extreme precision. To seek out even higher levels or precision and resolution, controlled performance must be boosted by achieving simultaneous multidirectional measurement. As the Laserscale continues to evolve, we will work to meet the needs of our customers.

Laserscale detection diagram