Legendary reliability, quality and Magnescale technology are all part of the Digital Gauge products.

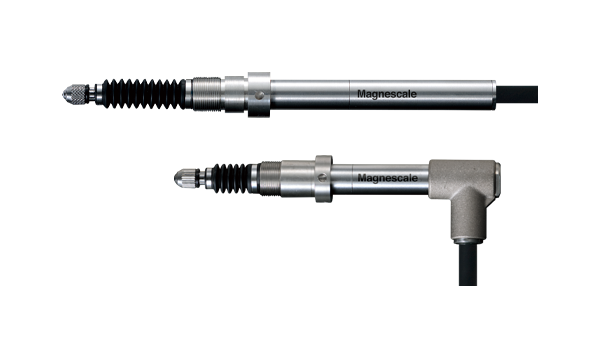

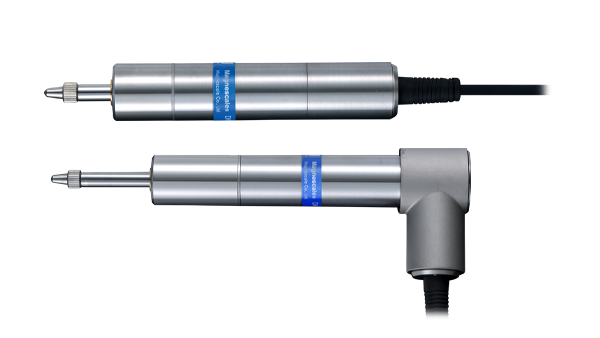

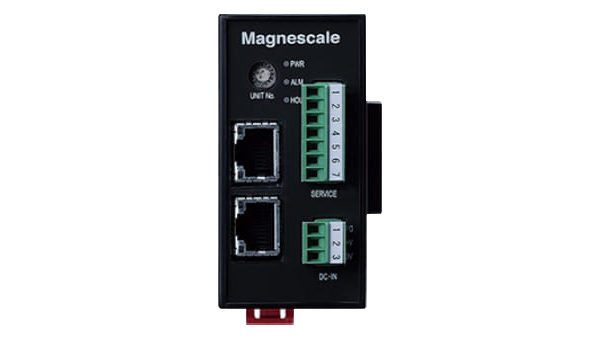

The Magnescale Digital Gauge products use a high-grade magnetic recording and detecting principle which has been developed over 50 years.The Digital Gauge products embody the reliability and quality that Magnescale is known for.Magnescale Digital Gauges feature high resolution and high accuracy, along with environmental, shock and vibration resistance that are a unique feature to our magnetic detecting principle.Sub-micron repeatability and improved torsion resistance comes from an innovative spindle design that enables environmental protection up IP67, allowing for a wide range of applications.

Features of Digital Gauges

-

MR sensor

Precise magnetic recordings are applied to a special proprietary magnetic material. Using a MR (Magneto Resistive) sensor with a unique detecting pattern allows for high accuracy, and also allows for high environmental resistance and strong resistance to temperature changes.

-

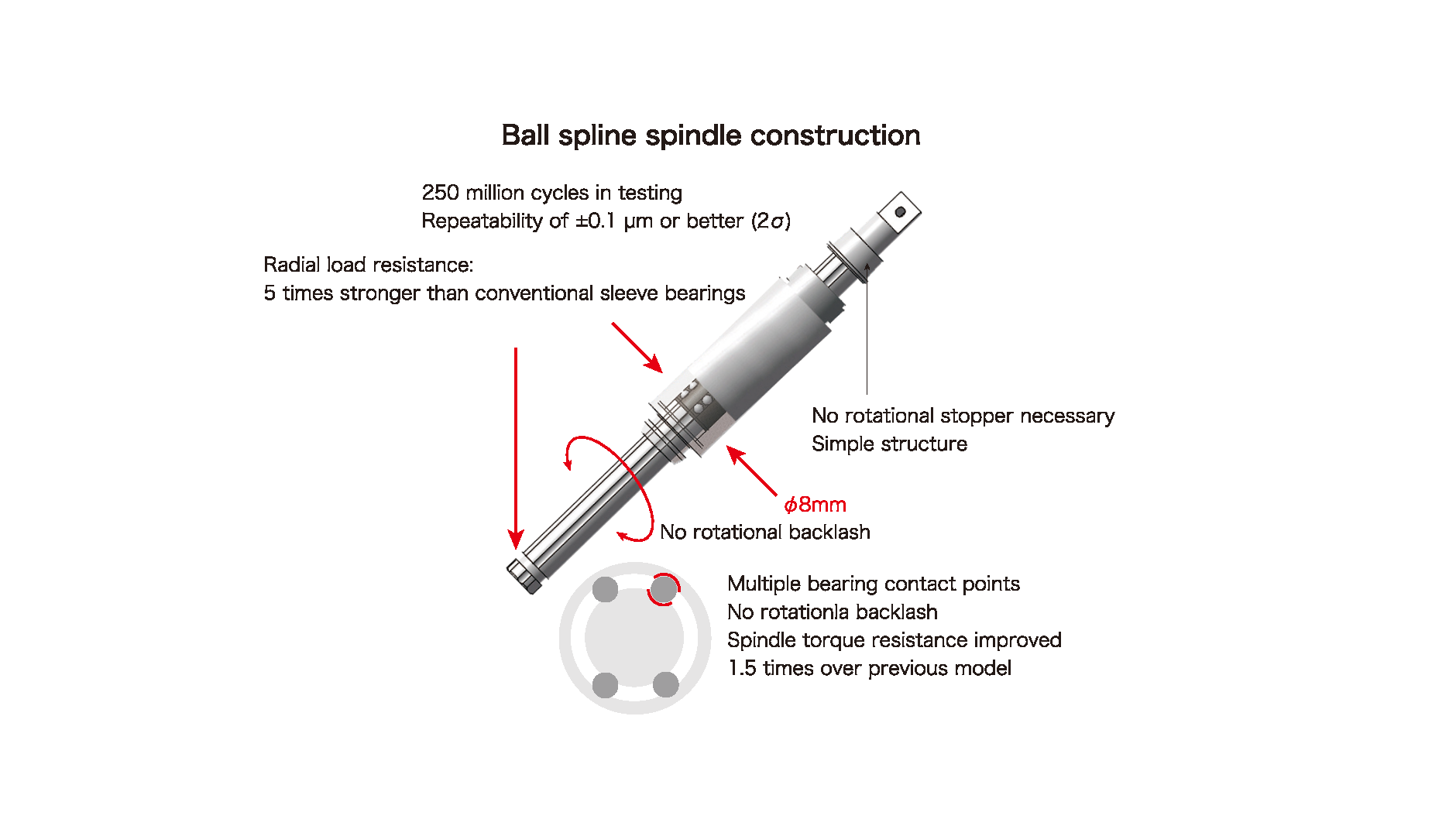

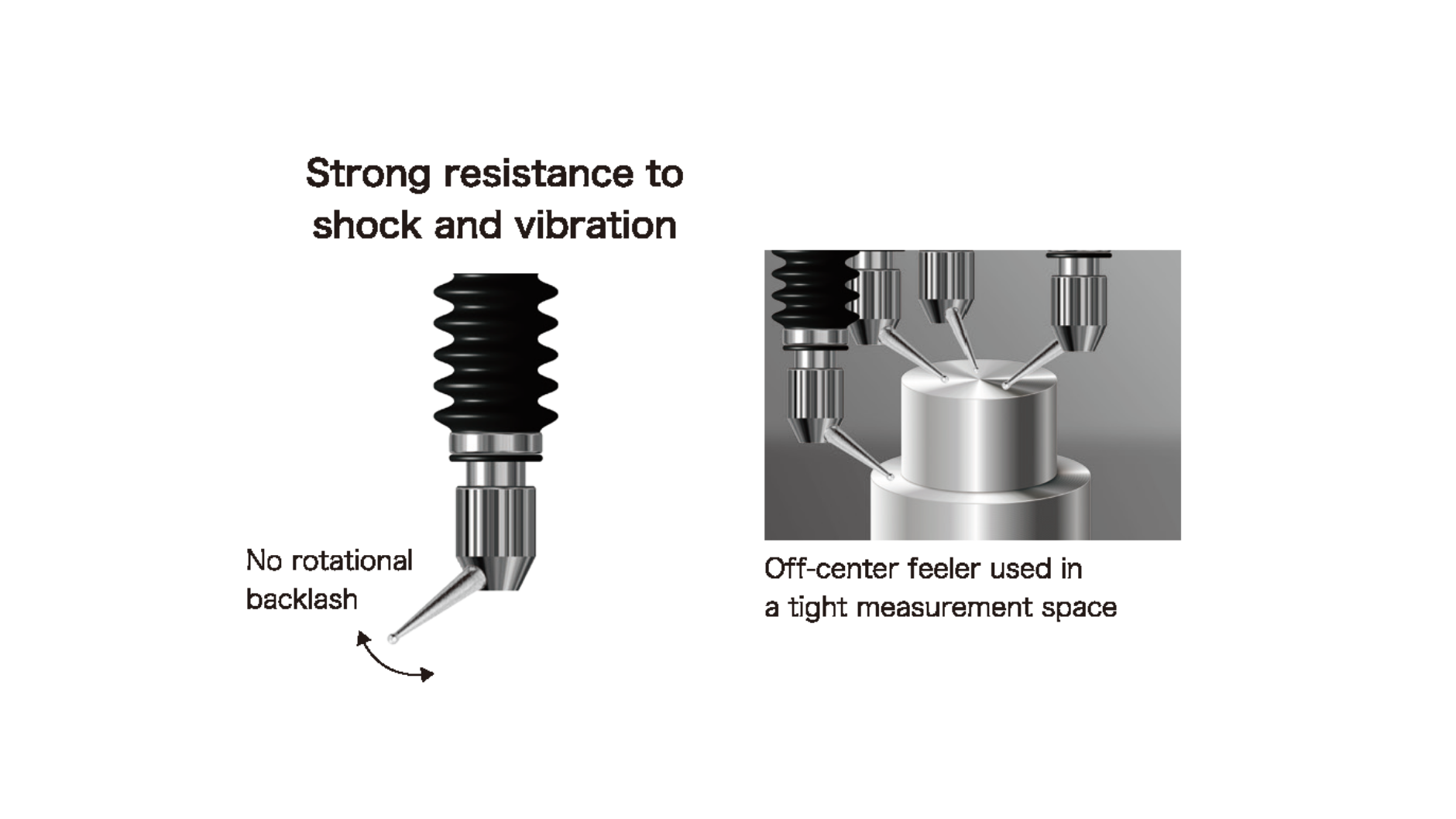

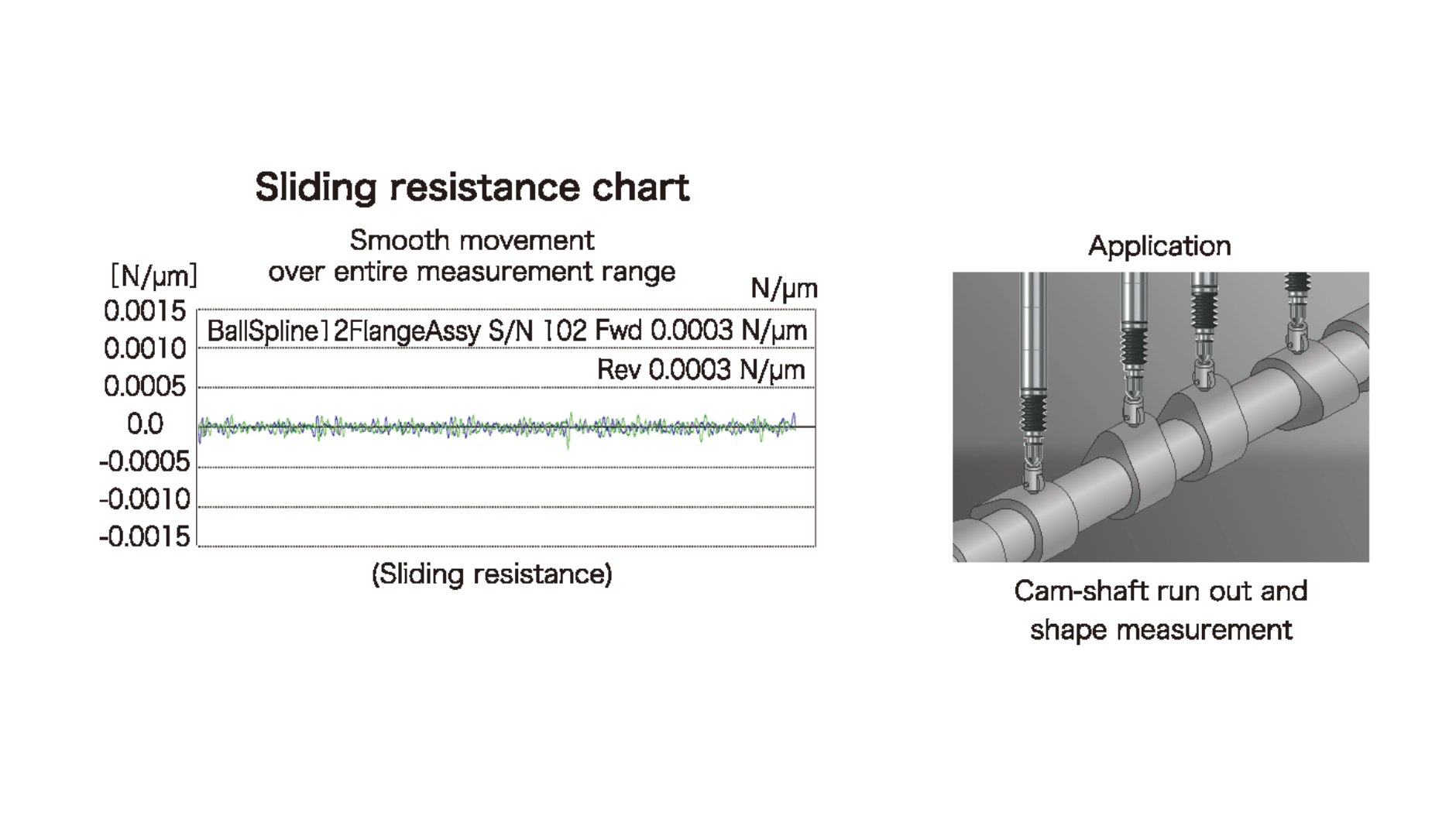

Ball spline spindle construction

The Digital Gauge has been improved with both repeatability and spindle performance due to the ball spline spindle construction. Long operational life, with excellent shock and vibration resistance help reduce overall maintenance costs.

-

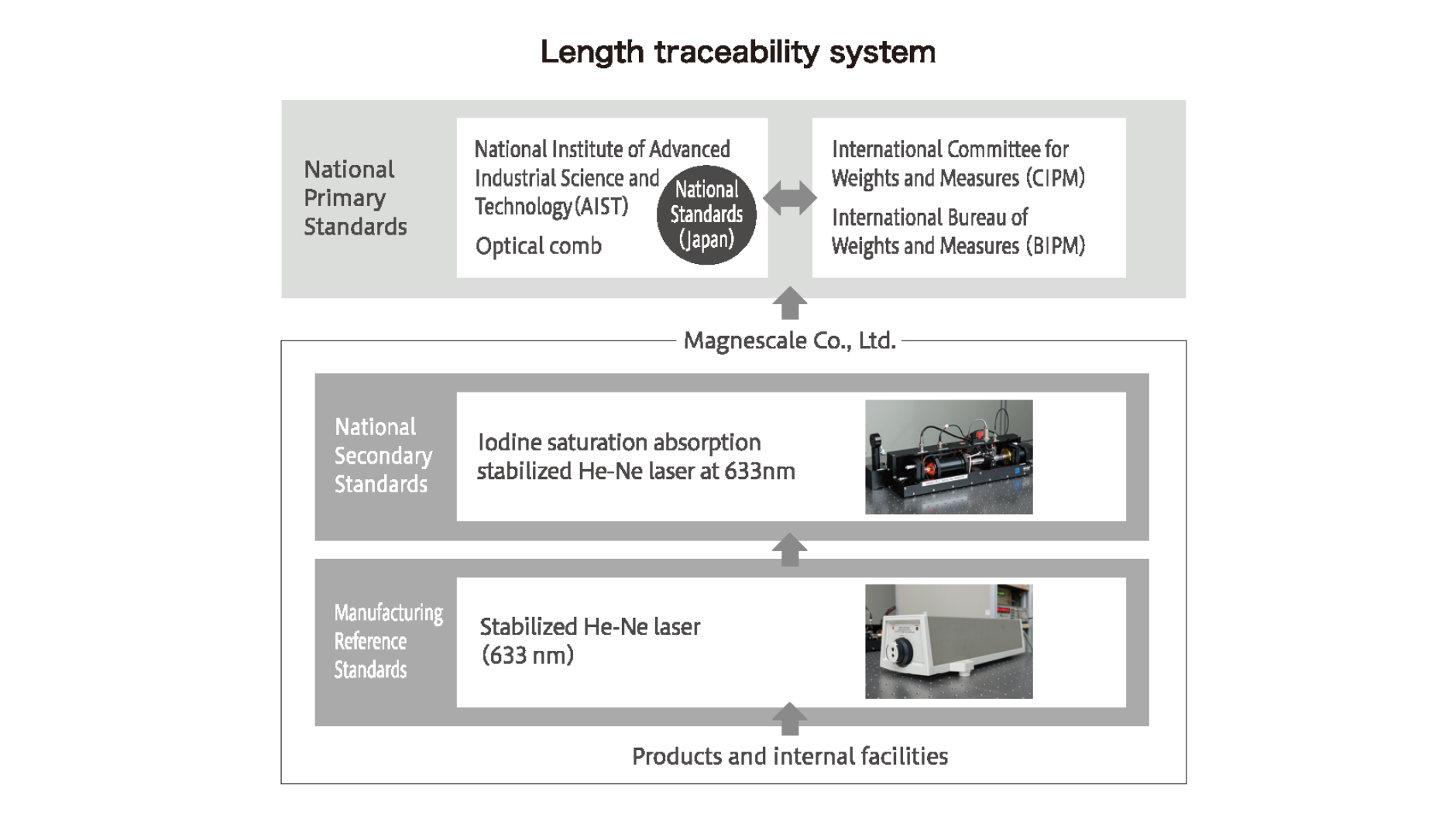

Traceability

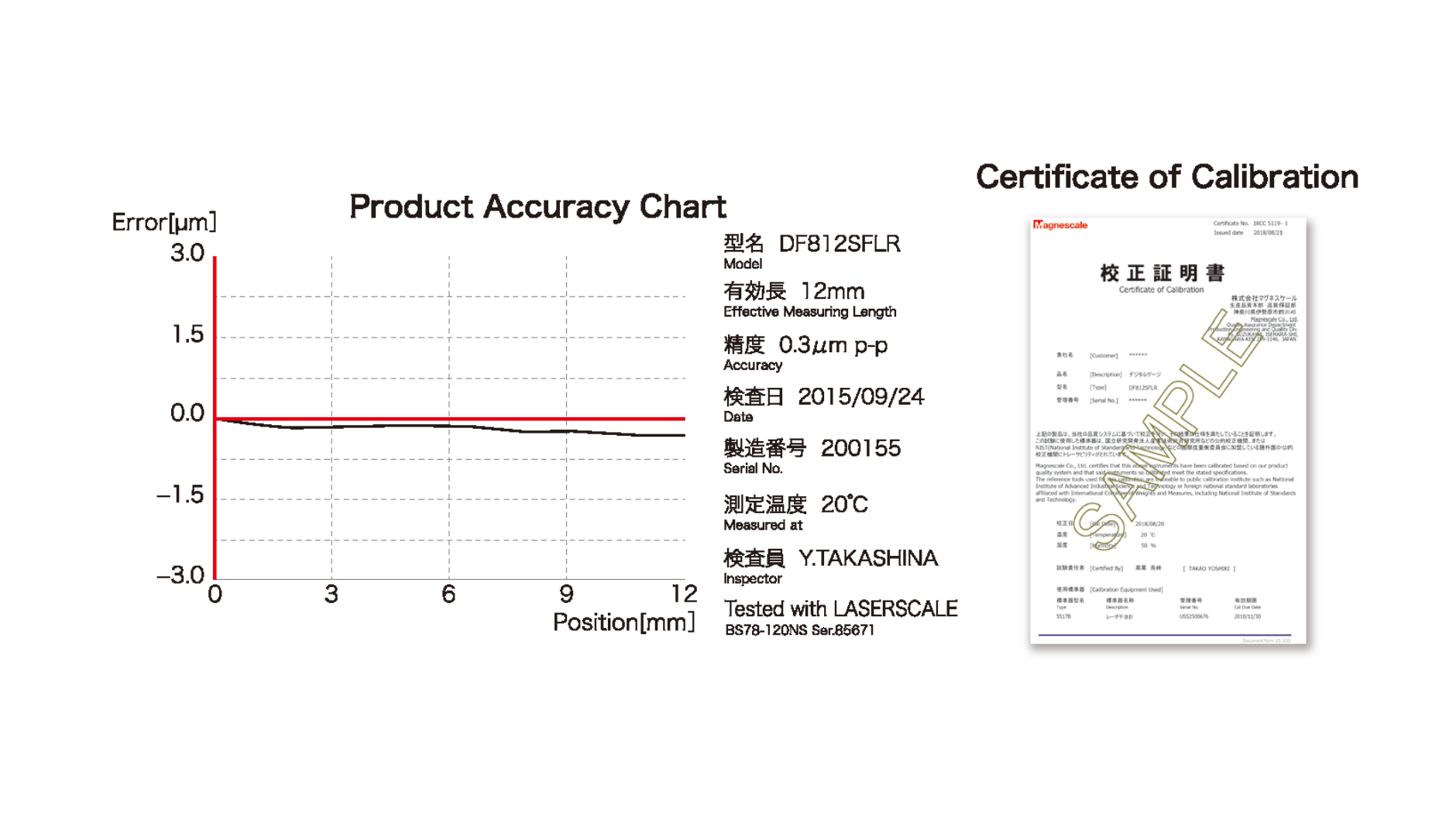

Magnescale Co., Ltd. is an authorized calibration contractor. An accuracy chart is attached with every product. Measurement data is generated by equipment traceable to national standards. Magnescale can also issue a calibration certificate after a products ships.

Technology topics

Applications

-

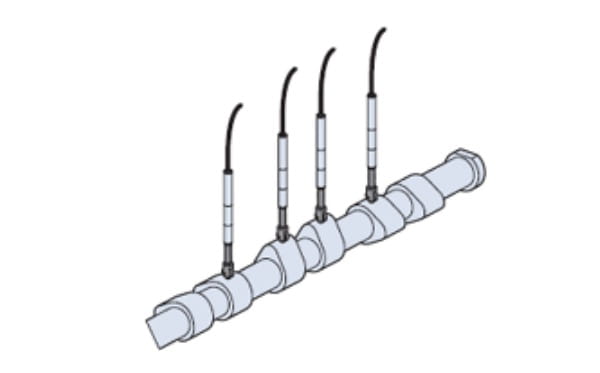

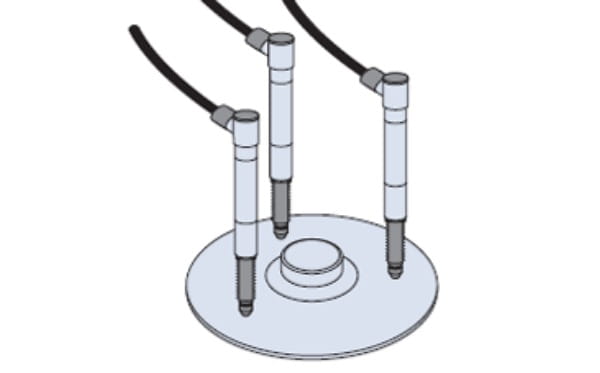

Camshaft displacement measurement

Measuring the lift of the camshaft. It is necessary to measure the peak (Max.) value accurately.

-

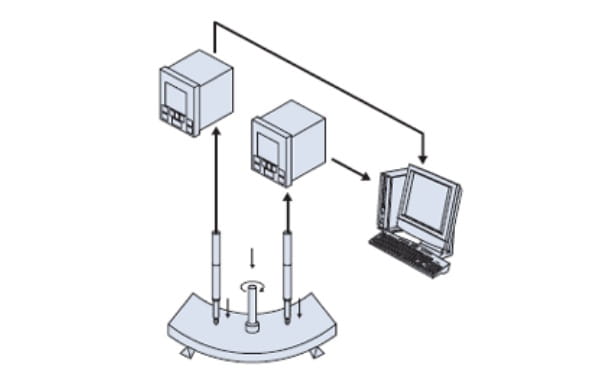

Measurement of material strength

Applicable for strength tests of various materials such as metal, resin materials and wood. Measuring unit is resistant to vibration.

-

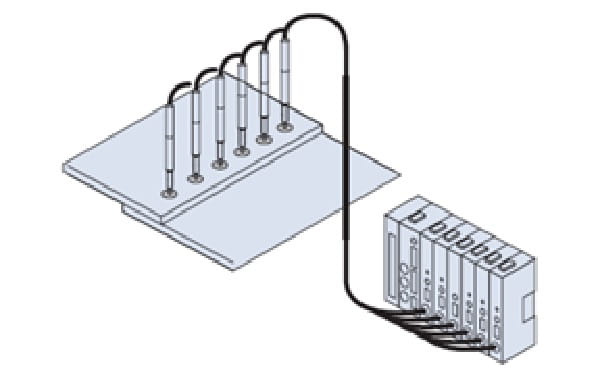

Multipoint measurement of liquid crystal panels

Measurement can be conducted easily in a small space by using a slim-shape measuring unit with fixture.

-

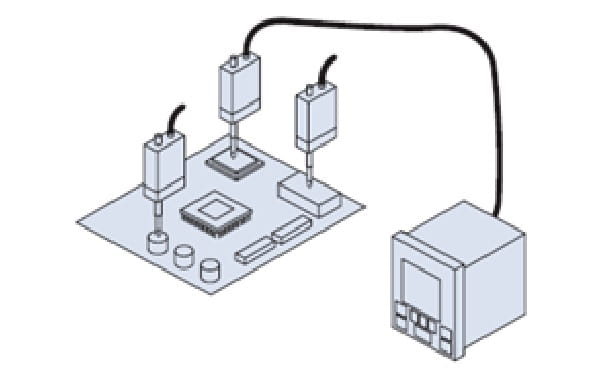

Measurement of the height of high-density mounting wiring boards

High-density measurement is possible with a slim-shaped measuring unit.

-

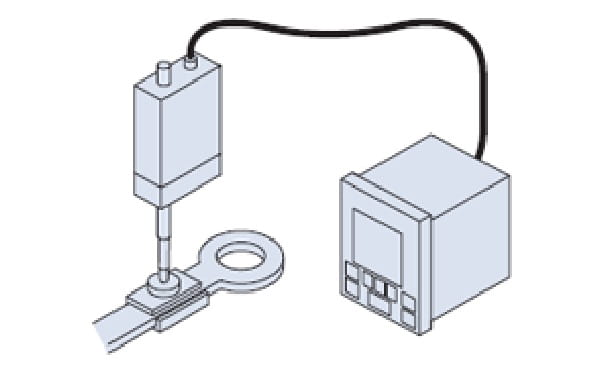

Measurement of crimp height

Measures the calking height of crimp terminal.

-

Measurement of fastener height

Measuring the height of screws in order to control the amount of torque.The small length measuring unit enables measurement at a narrow area.

-

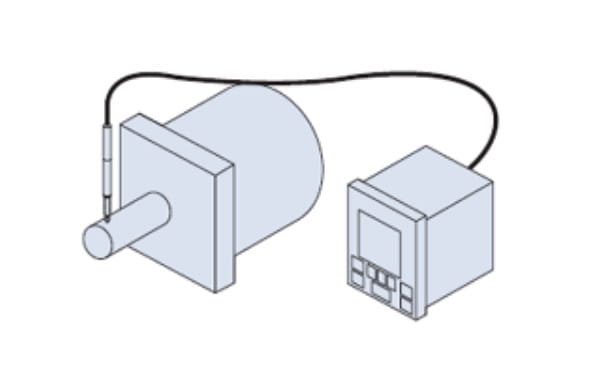

Measurement of motor shaft deviation

Measurement of a high speed spinning object is possible by utilizing a vibrationresistant gauge.

-

Measurement of hard disc flatness

Measuring the flatness of mass-produced discs.